Delta4 Machine QA

Advanced machine QA done in a few minutes

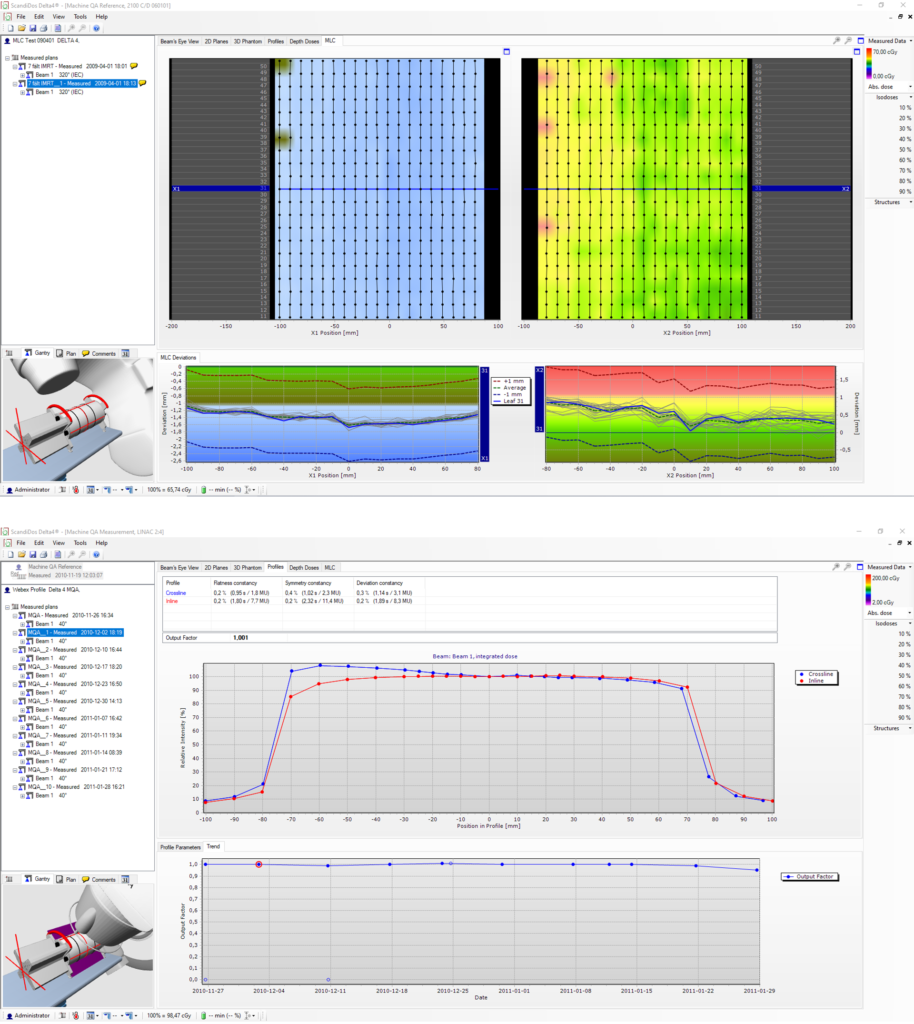

The Delta4 MachineQA software option for fast data acquisition and advanced data analysis allows you to perform QA of your linac, specifically in relation to rotation, start-up behavior, and dynamic beam modulation.

Easily define the test sequences that allow you to perform extended accelerator QA for IMRT and VMAT—in just a few minutes.

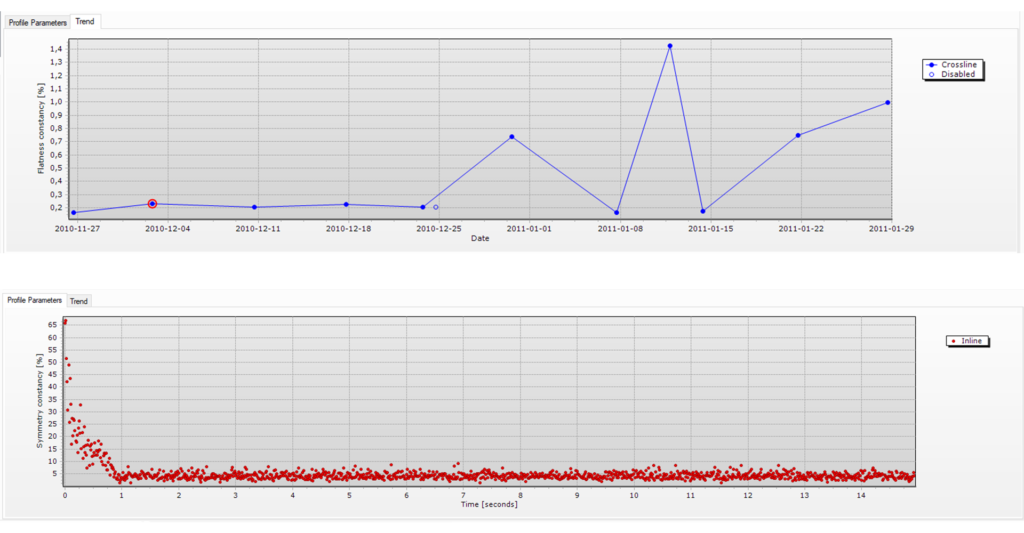

Periodic machine QA and analysis of constancy

Did you know that measurements made by the Machine QA option for your Delta4 system can be compared with TPS data or a reference measurement at any time? Reference measurements are typically obtained following maintenance and acceptance of the machine. The measurements can then be run directly in the RT machine’s service mode. Simply set up the configuration directly in Delta4.

Alternatively, the Machine QA option lets you create a DICOM RT Plan file including all tests to be performed, profiles, depth doses, and MLC checks, all at the same time! The QA routine can then be stored in the record-and-verify system and run over and over again on demand.

This routine can be easily added and run as part of pre-treatment verification with Delta4—and save you loads of time. As always with Delta4, analysis can be done at a later time according to your preference.

Contact Us

Delta4 takes machine QA to an advanced and efficient level

Delta4 takes machine QA to an advanced and efficient level

Contact us!

Book a virtual demo

Get the answers you need, connect with a Delta4 expert!